What we do

The Office of Sustainability (OOS) works with partners around the city to improve quality of life in all Philadelphia neighborhoods. We work to:

- Advance environmental justice.

- Progress Philadelphia’s climate and energy goals.

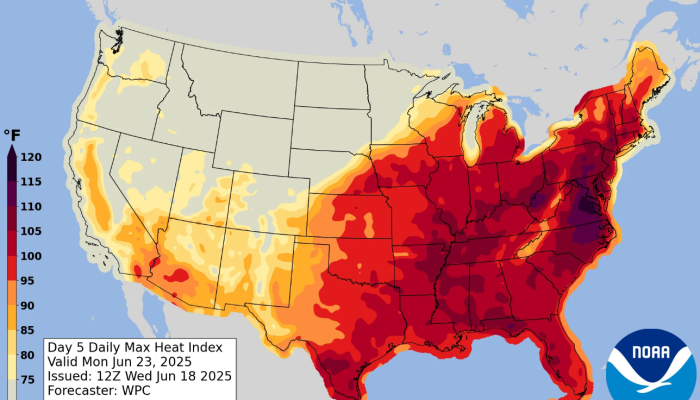

- Prepare the city for a hotter and wetter future.

OOS is made up of four divisions that carry out our programs, policies, and strategies.

- Climate Resilience

- Energy and Climate Solutions

- Environmental Justice

- Policy and Strategic Initiatives

For more on what we do, read about our divisions.

Connect

| Address |

One Parkway Building

1515 Arch St., 13th Floor Philadelphia, PA 19102 |

|---|---|

|

sustainability |

|

| Phone |

Phone:

(215) 686-3495

|

| Social |

Get involved

Stay informed and join our work through our newsletter, events, and social media posts.